NZE688D rated loading 6.5 ton

dual motor 350kwh (316kwh optional)

heavy duty mining charging electric wheel loader

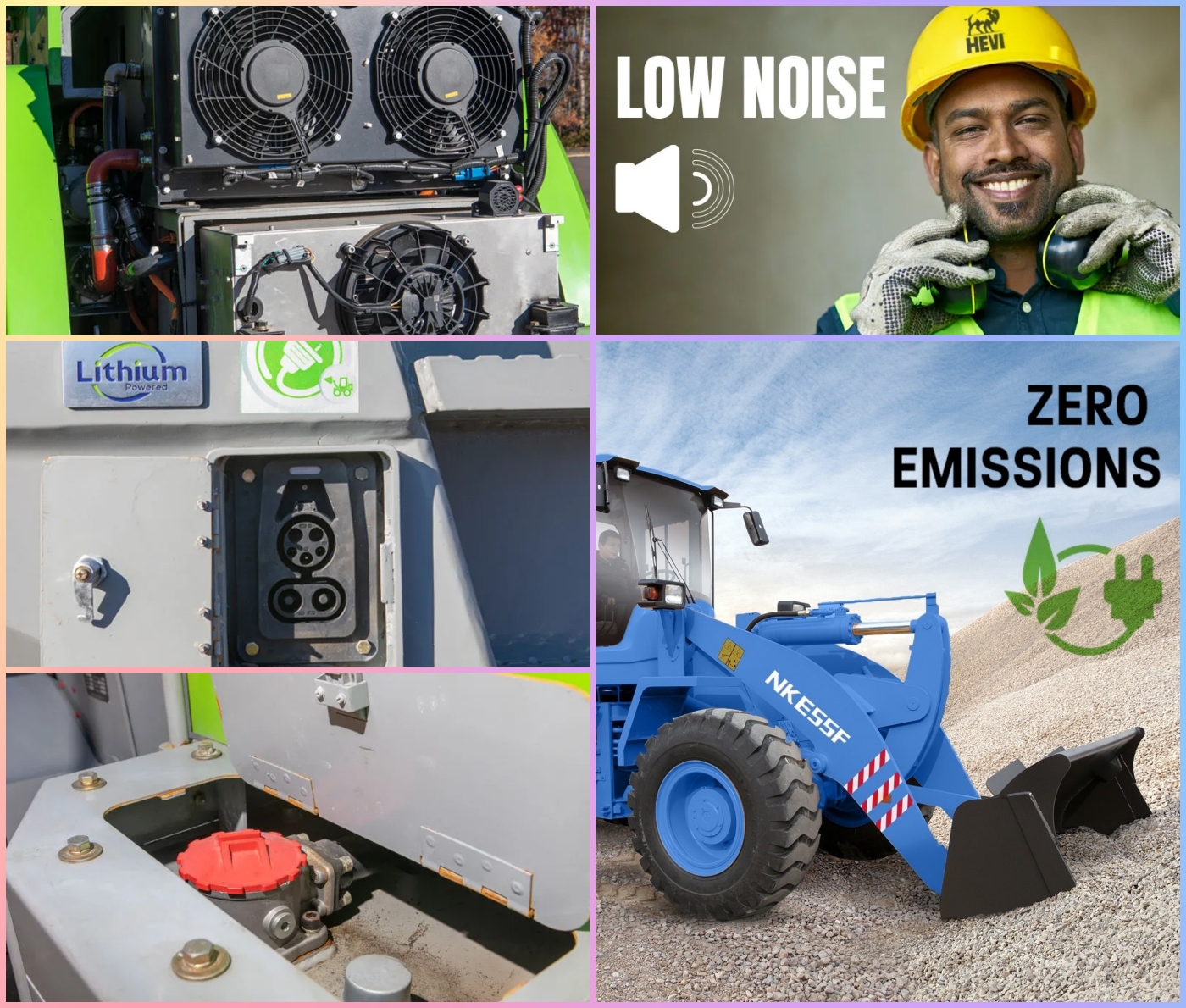

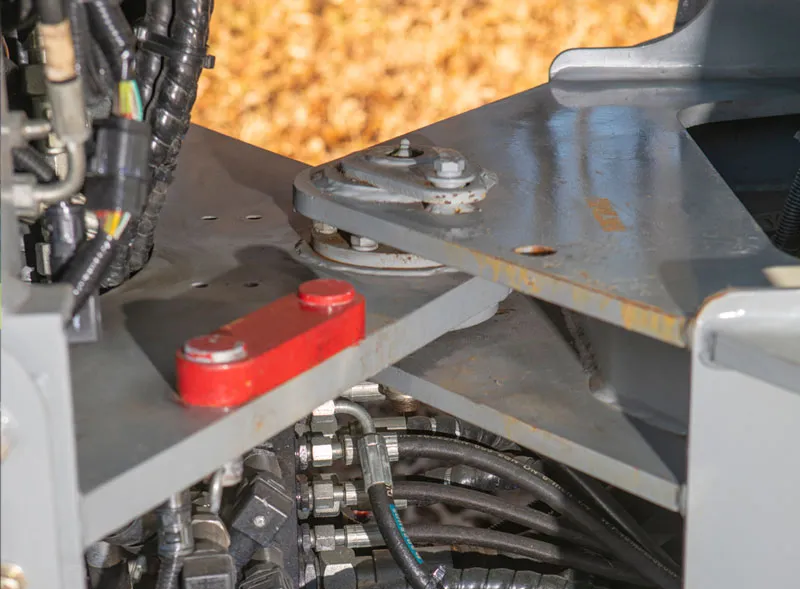

Adopting electric wheel loader has multiple benefits for operators beyond a reduced carbon footprint and sustainability benefits. With a significant reduction in moving parts and components, no requirement for fossil fuel combustion or storage and virtually no need for consumables such as engine oil, the total cost of ownership is significantly lower than ICE based counterparts. In addition, zero operating emissions and sound levels 60% lower than traditional machinery, means improved working conditions and health & safety benefits for operators.

Q1: How long does the NZE65F run on a full charge?

A1: Depending on workload and application, the 350 kWh battery supports 6–10 hours of continuous operation.

Q2: What is the charging time for the loader?

A2: Standard charging takes 6–8 hours, while fast charging can recharge the battery within 2–3 hours.

Q3: Is the NZE65F suitable for cold or high-altitude environments?

A3: Yes. The loader is designed with advanced thermal management and plateau-type adaptability, ensuring reliable performance in harsh conditions.

Q4: How does maintenance compare to a diesel loader?

A4: Electric loaders require fewer oil changes and engine repairs, reducing maintenance costs by up to 30–40%.

Q5: Can the NZE65F be customized for specific applications?

A5: Yes. OEM/ODM services are available for tailored solutions, including battery capacity, attachments, and working conditions.

Upgrade your fleet with the NZE65F 6.5-Ton Dual-Motor Electric Wheel Loader. Contact Know-how now to discuss specifications, customization options, and pricing.

Sustainability (Battery,Charging port,Low noise Pollution,Zero Emission,Low maintenance)

Performance (Operation Time/Charging Time,Large Bucket,High Range Articulation)

Comfort(Air Conditioned Cab,Premier Seat Suspension,Controls,Display)